Introduction

LDAR for fugitive emissions detection is widely used in Europe both in standard mode according to EPA Method 21 Technique (CWP Current Work Practice) and in SMART mode with Infrared Camera Optical Gas Imaging Technique (AWP Alternative Work Practic). SMART LDAR is only applicable in oil and gas fields in which both techniques are suitable and can be combined to enhance the results of the inspections.

At the end of 2008, EPA confirmed that these techniques can be considered equivalent under specific conditions.

First, it needs verification if the IR Camera is able to detect the compound of the area under survey. Secondly, since the camera is not able to detect the small leakers, the frequency of the inspections needs to be increased. In Europe, the SMART LDAR restrictions have almost disappeared and often the AWP inspections are carried out with discretionary procedures or without procedures. Just few European documents offer right guidelines about SMART LDAR and surely the most complete is the “Netherlands Technical Agreement – NTA 8399”.

EPA Method 21

Before introducing the guidelines described in NTA 8399, it could be interesting to know the main concepts of the standard LDAR. The Leak Definition is the emission threshold (ppmv) over which the equipment, monitored according to the EPA Method 21, becomes a leaker and has to be repaired. The whole condition of the equipment leaks is measured by the Fraction Leaking which is the ratio between the number of leakers and the number of equipment leaks monitored (Inventory). The Frequency of Monitoring is the number of inspections per year and the Effectiveness is the VOCs emission saving due to the LDAR implementation.

VOCs savings almost identical

The SMART LDAR (AWP) is equivalent to the CWP LDAR if it can reach the same effectiveness in terms of VOCs emissions saving. Where applicable, an IR OGI Camera is able to find the large leakers while the CWP EPA Method 21 is able to intercept both the small and the large leakers. After repair, the VOCs saving will be almost the same, independent of the monitoring technique.

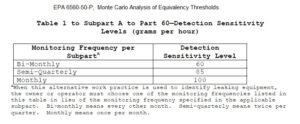

If the AWP frequency of the monitoring has increased or decreased according to the detectability of the specific sample fluid representative of the Plant Unit under inspection, the equivalence between the two methods becomes perfect or, in other terms, there is no preference for either approach.

These conclusions are reported into the technical paper “Monte Carlo Analysis to define Equivalent Leak Definitions for SMART LDAR when using optical gas imaging” (Epperson, Lev-on, Siegell, Ritter) and have been adopted by EPA in the final rule EPA 6560 – 50 – P “Alternative Work Practice to Detect Leaks from Equipment”.

It is reasonable at this point to assume that an unplanned SMART LDAR monitoring certainly cannot be considered effective and decisive for identification of the leakers.

Wind effect

For those who still have some doubts, let’s see what other difficulties arise when implementing an IR OGI inspection. What is the camera able to see and what are the environmental interferences that can reduce the probability to identify a leaker?

The camera is equipped with an optical filter for working in the range of Wavelength close to 3.40 μm, which is the IR absorbance of methane and it is close to those of aromatic and alkane compounds. Depending on the mass fraction and the number of detectable chemicals in the whole compound, which is the heavier between those of the Plant Uniti under examination, it is possible to qualify the detection sensitivity level achievable during the IR OGI monitoring at the Plant Unit. The tests carried out in a laboratory with controlled emissions regulated with orifices show that the monitoring distance reduces the probability to detect the emission. Introducing the wind effect, the detectability gets worse quickly because the “plume” becomes visible only if the leakage is more and more larger (the detectability is inversely proportional to the distance and the wind speed; for example the detection limit of methane increases from 2 g/h at wind speed of 7,2 km/h up to 11 g/h at a wind speed of 13,7 km/h from 10 meters; from 20 meter the detectability increases again almost linearly).

Other weather conditions

Apart from distance and wind speed, there are other weather conditions, including air temperature, humidity, cloud cover and solar radiation, which could cause eventually the failure of the monitoring. For this reason, weather conditions and the monitoring distance need to be qualified.

In order for the IR OGI Camera to detect the leakage, there must be a difference between the background radiation and the radiation emitted by the VOCs emissions. If an equipment is isolated or on the contrary many equipment are aggregated in few cubic meters, the scenario for the IR OGI filmmaker is different.

The NTA 8399 recommends that it is needed to quantify the number of different angles from which the images have to be caught for minimizing the impact of the background and for maximizing the chance to identify the leakers. This approach allows also to quantify how much time the monitoring requires and the inspection costs.

Unsatisfactory results

The NTA 8399 describes all the issues that have been briefly/previously discussed, giving guidance to the LDAR Manager in planning a correct SMART LDAR program. For this reason the NTA 8399 is among the documents that are not only useful but indispensable for this specific task. Coming back to the question that we asked ourselves at the beginning: “Is SMART LDAR correctly applied today in Europe?”, it is easy to say that, where applied, the research on the compounds detectability and the frequency of the inspections were modest, but nevertheless the results have been often interesting. In a first cycle, the initial one from 2008 until 2012 and mainly in the countries that were a little late about the LDAR regulations, like Italy, UK and Spain, the SMART mode was used substantially to fulfill, at the minimum possible cost, some environmental obligations, as was the aim of SMART LDAR. The results, however, were extremely unsatisfactory and in some cases really inaccurate, because often the number of leakers identified during the inspections was very small also in case of large inventory inspected.

Additional instrument

But quickly some End Users understood the usefulness of the instrument (IR OGI Camera) as an additional instrument for specific tasks such as the inspection of the floating roof tanks, the assistance to the Plant Start-Up after Shut Down, the localization of large leakages the presence of which were pointed by the smell but couldn’t be found. Today the SMART LDAR IR OGI inspection surely has been downsized compared to the initial ambitions in its capacity for identifying fugitive emissions. Firstly, because now we know better the limits of the IR Camera, which is not able to detect fluids too far from the Wavelength radiation of 3.4 μm. Moreover, even in case the fluid is in the right Wavelength range, only the large emissions are usually detectable. Secondly, we now have experience that environmental influences and monitoring procedures have stronger interferences on the monitoring than previously expected. But in the same time it has become an indispensable tool for plant safety because it is able to support the resolution of criticalities in a perspective of Direct Inspection and Maintenance – DI&M. In relation to the LDAR program, after almost 20 years of antagonisms between the two CWP and AWP inspection techniques, it can be concluded today that the best LDAR program is the one that adopts in the same time both techniques.